If you’re looking to get involved in the brick making industry, then the first thing you need to do is invest in a quality brick making machine that’ll get your business up and running in no time at all.

However, something you need to be careful attention to is the brick making machine price you pay, along with the features that the machine can offer you. In this guide, we’re going to take a closer look at what you should expect from a high-quality brick making machine, so let’s get straight to it.

First of all, it’s important to note that the brick making plant price you pay can vary by quite a margin, depending on the features it has to offer and where you purchase it from. In many cases, it’s possible to secure excellent deals by purchasing the machine directly from China, where many of them are made in the first place. This will allow you to secure a very competitive rate, and it will ultimately help you to secure an excellent return on your investment much faster than you otherwise would be able to.

Another thing to bear in mind is that the success of your brick making business largely depends on the quality of the finished product you are able to produce. Ultimately, this means you do not want to skimp when you are purchasing the machine, as a low-quality machine is likely to make a low-quality finished product, and this will hurt your business in the long run.

Something else you will also want to think about is the kind brick you’re hoping to make, as while most bricks tend to have a general standardization, there are certainly different types of brick that are better for different types of climate. As an example of this, some bricks can be highly effective when it comes to insulation, and they have a useful passive solar heat retention property that makes them great for different climates.

On the other hand, bricks that have a high clay content can be easier for molding into different shapes, and these kind of bricks can be used to give a wide variety of different customization options that you may wish to provide your customers.

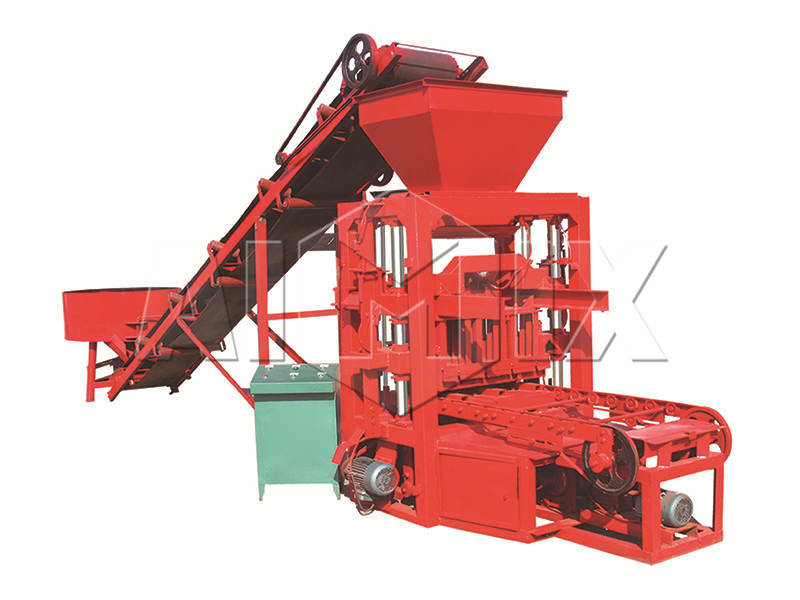

Fortunately, the process of making bricks with a new brick manufacturing machine doesn’t have to be too complicated at all, and the basic process will consist of crushing, grinding, and screening the raw materials to produce your brick. Once you have all the raw materials gathered and ready for use, they can be left to set and dry for quite some time until they’re ready to be fired.

Once your bricks have been fired, the last thing to do is to package up your inventory and get them ready for the final processing.

In summary, it’s clear to see that starting a new brick making business can be a fun and fulfilling endeavor for anybody who is looking to get into this kind of industry. The first step will always get high-quality fly ash brick making machine price list, and the better machine is, the easier your business life will become. You can click here to know more about Aimix brick making machine.