The construction industry in Indonesia is experiencing rapid growth and development, driven by infrastructure projects, urbanization, and economic expansion. In this dynamic landscape, batching plants have emerged as a key technology that is advancing the industry. Batching plants provide a centralized and efficient method of producing high-quality concrete for construction projects. This article explores the pivotal role of batching plants in advancing the construction industry in Indonesia. From improving productivity and quality control to promoting sustainability and driving innovation, batching plants are revolutionizing the way construction projects are executed in the country.

Enhanced Productivity and Efficiency

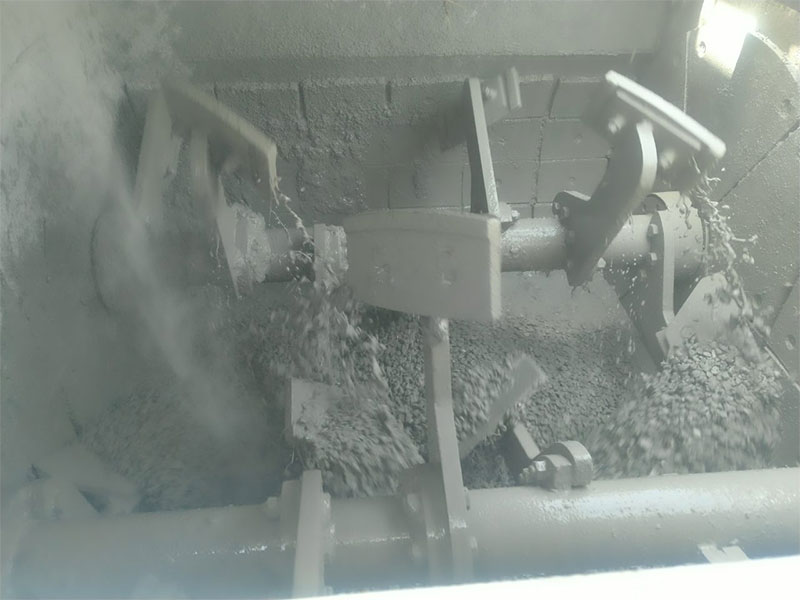

Batching plants have significantly enhanced productivity and efficiency in the construction industry in Indonesia. By centralizing the production of concrete, batching plant portable eliminates the need for manual mixing on-site, saving time and reducing labor requirements. The automated and computerized systems in batching plants ensure precise batching, accurate measurement of ingredients, and consistent mixing, resulting in a higher-quality product. The efficient production process of batching plants allows for faster construction progress, reduced waiting times, and improved project timelines.

Quality Control and Consistency

Batching plants play a crucial role in ensuring quality control and consistency in concrete production. The advanced technology and control systems employed in batching plants allow for precise measurement of materials and accurate mixing. This results in a uniform and consistent concrete product, which enhances the structural integrity and durability of constructed infrastructure. Batching plants enable construction companies in Indonesia to meet stringent quality standards, comply with industry regulations, and deliver high-performance structures.

Sustainable Construction Practices

Batching plants are driving sustainable construction practices in Indonesia. By utilizing ready-mix concrete produced at centralized jual mini batching plant, the carbon emissions associated with on-site concrete mixing and transportation are significantly reduced. Batching plants also enable the use of supplementary cementitious materials and recycled aggregates, promoting the sustainable use of resources and reducing the demand for virgin materials. The precise batching process and optimized mix designs minimize material waste, improving resource efficiency and reducing environmental impact. Batching plants are helping construction projects in Indonesia achieve green building certifications and contribute to the country’s sustainable development goals.

Innovation and Customization

Batching plants are fostering innovation and customization in the construction industry in Indonesia. These plants offer flexibility to produce different types and grades of concrete, allowing for customization based on project requirements. Batching plants facilitate the use of specialized concrete mixes such as high-strength concrete, self-compacting concrete, and fiber-reinforced concrete, enabling construction companies to meet specific design and performance criteria. Moreover, batching plant beton is driving technological advancements in automation, control systems, and data management, leading to improved efficiency, accuracy, and optimization in concrete production processes.

Collaboration and Industry Integration

Batching plants are promoting collaboration and integration within the construction industry in Indonesia. These plants from Aimix Group Co Ltd act as central hubs where construction companies, suppliers, and contractors converge. Batching plants enable close collaboration between stakeholders, facilitating the sharing of information, resources, and best practices. They serve as platforms for knowledge exchange, where industry professionals can discuss and implement innovative solutions. Batching plants also support the integration of construction processes, allowing for seamless coordination between concrete production, delivery, and placement. This integrated approach improves project coordination, minimizes delays, and enhances overall project performance.

Conclusion

Batching plants are revolutionizing the construction industry in Indonesia by advancing productivity, quality control, sustainability, innovation, and collaboration. They have become integral components in construction projects, enabling efficient and centralized concrete production. With their ability to enhance productivity, ensure consistent quality, promote sustainability, drive