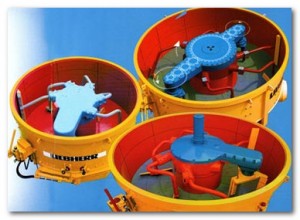

Concrete mixers are devices that are used to combine cement, gravel, sand and water to make a homogeneous mixture that is called concrete. Pan mixers have vertical axis mixing blades that make for small volumes of the required product.

Pan mixers have small capacities and are favored equipment for small builders and those who have to deal with smaller volumes. They are also very ideal for mixing batches of mortar and grout needed for brickwork, plaster and flooring. The basic configuration of a concrete mixer is a drum which has blades inside that constantly churn the mixture of cement, aggregates and water to make the mixture uniform. It is in this drum that the process of mixing takes place and produces the required concrete, grout or screed.

Pan mixers have small capacities and are favored equipment for small builders and those who have to deal with smaller volumes. They are also very ideal for mixing batches of mortar and grout needed for brickwork, plaster and flooring. The basic configuration of a concrete mixer is a drum which has blades inside that constantly churn the mixture of cement, aggregates and water to make the mixture uniform. It is in this drum that the process of mixing takes place and produces the required concrete, grout or screed.

This same principle is carried forward, when batches required are bigger, and the equipment gets more sophisticated, with batching plants nowadays all computer controlled, where the weighing and mixing is all controlled to ensure perfect quality. Pan mixers are equipment that is normally placed at the site of construction and allows concrete to be used immediately before it dries out. The control of these mixers is with the workers who can decide on the speed of the work as per actual conditions at site.

Pan mixers for concrete have to be maintained clean if they are to give the required service over long periods of time. This requires their drums to be kept clean and rid of all previous batches, so that the volume in it does not reduce. Concrete can set to form very hard layers in pan mixer drums, which can steadily build up and reduce the volume of the pan and hence affect productivity in the long run. Pan mixers normally operate with diesel engine supplying the motive power to rotate the vertical axis blades that ensure the mixing.