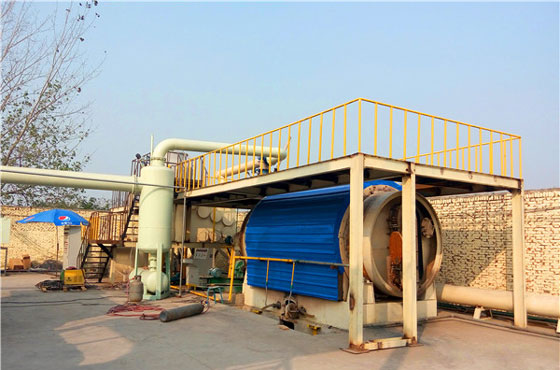

Increased non-biodegradable wastes from plastic and rubber pose a great danger to the environment. Pyrolysis equipment has been specifically designed to convert organic waste to useful end products which include liquid fuel, gas and solid residue. The plant provides suitable conditions for pyrolysis reaction to take place under high temperature in absence of air. This converts the waste products to useful alternative source of energy with low impact on the environment. This helps reduce use of fossil fuels which face the risk of exploitation and associated with air pollution. Firms engaging in different manufacturing processes can consider investing in small scale plastic recycling plant in an effort to conserve the environment.

The following are benefits of using small scale plastic recycling plant

It is cost effective

The small scale plastic waste pyrolysis plant is affordable for business dealing with organic wastes like plastic and rubber. A firm can consider investing in this plant as either the main core business or as an alternative to recycle waste products resulting from main manufacturing activities. In the long run, the company will save the cost incurred in disposing organic wastes by converting it to useful products. Final products can be used to provide reliable source of energy to run different manufacturing machines thus saving the cost of production and increasing the profit margin. Pyrolysis plant is fire-risk free since it does not use oxygen in combustion making it a safe investment option.

Comply with environmental legislations

Every manufacturing firm is required by law to observe safe environmental practices while engaging in its activities. Before commencing manufacturing activities, a business is required to indicate efforts in place to reduce harmful environmental impacts resulting from its activities. A company can ensure compliance with this legislation by investing in small scale plastic recycling plant. The benefits involved in investing in small plastic recycling machine far much outweighs the alternative cost to be incurred in order to comply with waste management.

Environmentally friendly

Pyrolysis plant help avoid exposure of harmful organic wastes to the environment, thus helping in conserving the environment. Plastic and rubber are made from strong hydrocarbons bonds that cannot decompose when left in the environment. When exposed to the nature, they pose a great risk to natural ecosystem thus compromising the future of animal and plant species. Small scale plastic pyrolysis machine plays a great role towards encouraging continued natural ecological processes and thus encouraging survival of different animal and plant species.

Waste product resulting from manufacturing and operational activities can be recycled to useful source of energy using the pyrolysis equipment. Pyrolysis liquid fuel can be separated into diesel, benzene or engine oil and used to power other manufacturing plants. Alternatively, the liquid can be wholly used to power boilers without fractionation. Solid carbon residue is used as a solid fuel and is an alternative for fossil coal and charcoal. It can also be used as a fertiliser to provide favourable conditions to grow crops. Pyrolysis gas which comprise of carbon monoxide and hydrogen is usually recycled to provide energy for pyrolysis process in the combustion chamber.